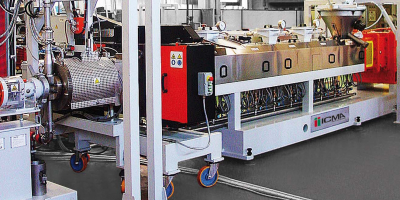

Recycling lines equipped with co-rotating extruders

How do plastic recycling equipment and extruders work?

ICMA's extruders melt and mix post-consumer and post-industrial plastics at the highest standard so that it becomes a reusable and valuable material. Simple.

When is it recommended the use co-rotating technology and extruders?

The co-rotating technology delivered by ICMA is appropriate to secure UP-CYCLING results and when:

- There is a need to process materials that are hardly recyclable with traditional technologies

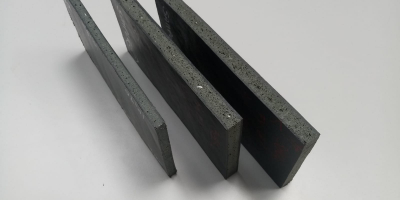

- You want to create a material with higher specifications to replace virgin materials in technical applications

- You need a very high production capacity. Companies that normally use single-screw extruders for recycling upgrades to co-rotating extruders to double their production capacity

Another advantage of co-rotating extruders is energy efficiency.

For this reason, the new MCM-HP family is well-suited for both compounding and direct extrusion uses

Notwithstanding all these assessments, it is still difficult to "sell" these benefits when you have to extrude a seemingly simple product.

Only the co-rotating technology has the unique opportunity to ADD fillers or reinforcements to the recyclate, thus securing a much larger and more profitable market opportunity.