PVC

Both for cable production and for other special applications like the non-toxic compound for the medical field, ICMA has engineered special compounding lines particularly designed to process rigid, soft, and hyper-filled PVC.

By using a co-rotating extruder, the process performance is better in comparison with a traditional counter-rotating extruder, both from the point of view of energy consumption and throughput per hour.

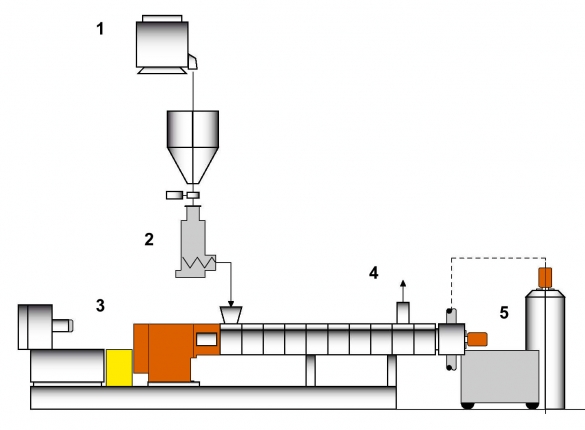

Soft or rigid PVC:

1 Turbo-mixer, 2 Dosing units, 3 MCM extruders, 4 Venting systems, and 5 Hot-face pelletizer.

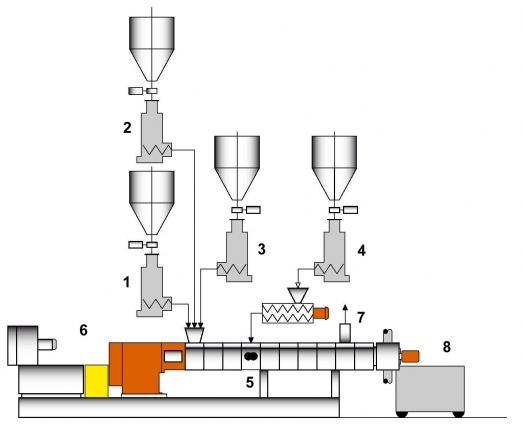

Rigid PVC:

1 Gravimetric feeding unit, 2 Gravimetric feeding units, 3 Gravimetric feeding units, 4 Gravimetric feeding units, 5 Side feeding units, 6 MCM extruders, 7 Venting systems, and 8 Hot-face pelletizer.