Co-rotating Extruders

What is a co-rotating twin screw extruder ?

A co-rotating twin screw extruder is an advanced engineered extruder specifically conceived for high tech processes where output rates are key to have a quality compound.

What are co-rotating twin screw extruders used for?

Incorporation of fillers, fibers and additives, blends from similar or different polymers, and homogenisation are typical tasks for there extruders.

Twin screw extruders are more and more used in several industries such as polymer, mechanical recycling, composite materials, chemical, and food industries.

Co-rotating inter-meshing designs were developed and applied for the first time in the 30s for mixing and pumping ceramic paste. The first commercial machine of this type was invented by Colombo from LMP (Italy) for thermoses and PVC processing. ICMA has made proper this precious background and today can offer a modern and advanced complete range of co-rotating extruders at max speed & torque from 18 to 175 mm, all already manufactured and in operation for our customers

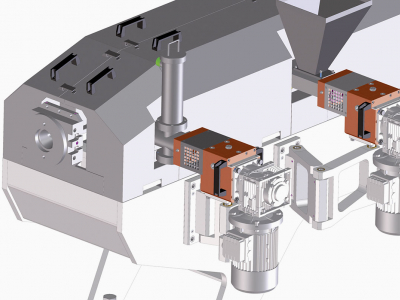

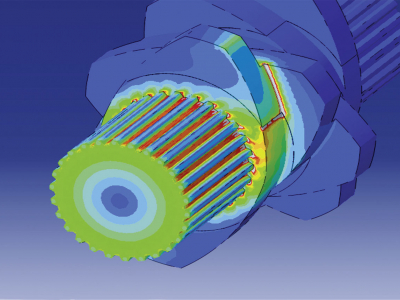

Extruders are designed according to the specific process and optimized to fully exploit the engineered modularity. High-performance barrels constructed of nitride steel can be supplied in different L/D ratios with air or water cooling system options and equipped with optional wear-resistant liners.

What are the advantages of Co-rotating extruders?

Here are some of the main processing advantages of Co-rotating extruders Technology:

- Highly flexible modular system

- Energy saving, low specific-energy consumption

- The high intake capacity of feed screws

- Fast recipe or color change due to self-wiping geometry

- High plastification capacity

- Calibrated control of melt temperature

- High homogenizing/distributive mixing capacity

- High dispersive mixing capacity

- Fine-tuning of residence time-shear/elongation stresses parameters balance

- High venting efficiency due to the large surfaces and the system modularity

The powerful machines can handle an extensive array of compounds and applications, and produce extrusion to the highest quality standards.

Technical features of a Co-rotating Extruder:

| Screw Diameter (mm) | Da/di | Md/a^3 (Nm/cm^3) per shaft | Maximum Screw Speed (U/min) |

|---|---|---|---|

| 18 | 1,55 | 12,5 | 1200 |

| 25 | 1,55 | 15 | 1200 |

| 30 | 1,55 | 18 | 1200 |

| 40 | 1,55 | 18 | 1200 |

| 50 | 1,55 | 18 | 1200 |

| 53 | 1,65 | 16 | 1200 |

| 60 | 1,55 | 18 | 1200 |

| 70 | 1,55 | 18 | 1200 |

| 80 | 1,55 | 18 | 1200 |

| 90 | 1,51 | 18 | 1000 |

| 96 | 1,65 | 15 | 1000 |

| 110 | 1,55 | 17 | 900 |

| 112 | 1,65 | 15 | 900 |

| 140 | 1,55 | 15 | 600 |

| 175 | 1,55 | 12,5 | 300 |

| 220 | 1,55 | 12,5 | 300 |