WPC & NFC Sheets

Pioneer in WPC sheets

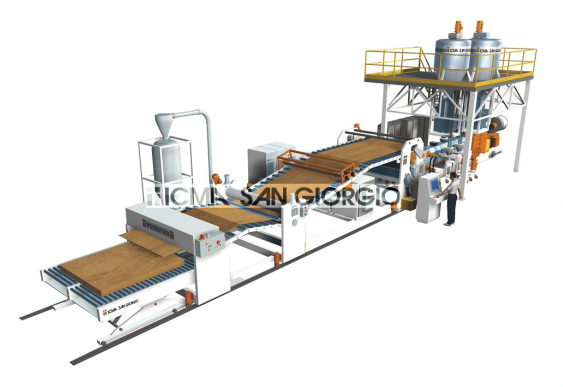

Our knowledge in mixing natural fibers and polyolefin roots back to the early 70s when ICMA successfully pioneered, first in the World, the process technology for producing a thermoformable sheet for automotive interior trims made of virgin or recycled polypropylene and wood flour.

This patented technology came to be known as WOOD-STOCK™ and became a worldwide success in the automotive industry with more than 50 plants worldwide, delivered during the last decades to the major car component manufacturers.

Compounding / Extrusion systems for Wood stock™ sheets and sheets filled with natural fibers — rice husk, coconut shell, hemp. Production output up to max 2,500 kg / hour.

The main applications are in the following industries:

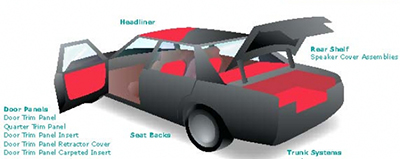

AUTOMOTIVE

The continuous search for materials that are both economic and resistant is key in the automotive industry. Woodstock is easily indicated as a natural support material and as a finished product when is molded, colored, and attached or laminated to other materials. From this factor stems the possibility of general application in the manufacture of vehicle bodies, from automobiles to trucks, from caravans to industrial conveyors.

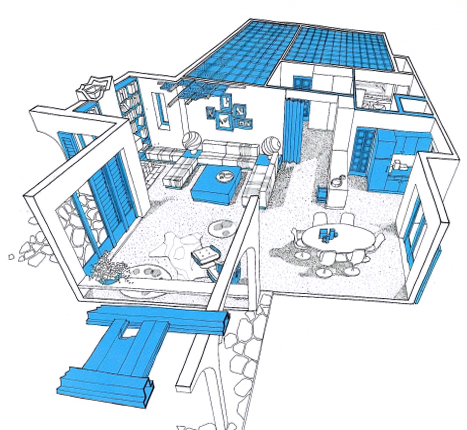

CONSTRUCTION

Thanks to its ductility and its adaptability, Wood-stock finds a vast application in the Construction industry. In the World, 70% of the traditional material for construction remains wood. This could be almost totally substituted by Wood-stock products which can be used from internal decoration to the building skeleton, doors, internal and external fittings, furniture, ceilings and so on.