The co-rotating technology delivered by ICMA secures UP-CYCLING results especially when:

- There is a need to process materials that are hardly recyclable with traditional technologies

- You want to create a material with a higher specification to replace virgin materials in technical applications

- You need a very high production capacity. In these cases, it becomes more and more frequently the case of companies normally using single-screw extruders to replace them with specially designed co-rotating extruders.

More:

- Another advantage is energy efficiency gained by using co-rotating extruders.

- The co-rotating technology has the unique opportunity to ADD fillers or reinforcements to the recyclate thus securing a much larger and more profitable market opportunity.

- ICMA also offers various tech solutions, also patented, for efficient odor removal to get high-quality recycling

Depending on the type of tasks required different layout can be designed. More details by clicking the following button.

HDPE - PP:

ORIGIN: Post-consumer liquid container bottles (milk, juice) jars (detergent) food trays, industrial bins, car fuel tanks

PRE- PROCES: Generally, come from a separation and washing system

PROCESS TASK:

- Mix the polymers with different viscosity

- Keep the polymer mechanical characteristics without degradation

- Perfect degassing for good post-processing (injection molding

- Fine filtration

REMARKS: Is a high bulk density material, easier to feed

TURN KEY LINE:

- Flakes and additive handling

- Loss in weight gravimetric system

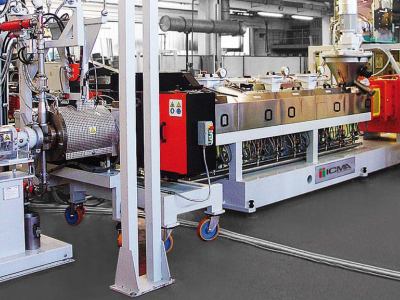

- High torque co-rotating extruder

- Continuous screen changer ( no firm links with suppliers)

- Water ring or underwater pelletizing system

- Final material handling and packing (big bags)

Proven screw geometry perfect melting/dispersion of very low MFI fraction

- Lower residence time under controlled shear & thermal conditions

- Multiple highly efficient degassing ports

- Double filtration system

ICMA's line FOR ALL PROCESSING TASK:

- Line including MCM 140 HT capacity up to 4,5 t/h

- Line including MCM 110 HT capacity up to 2,5 t/h

- Line including MCM 90 HT capacity up to 1 t/h

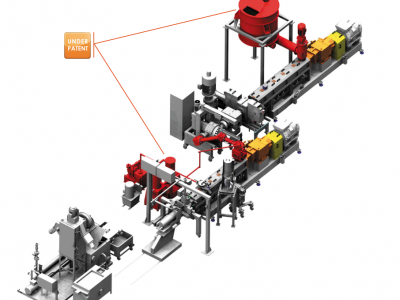

In Film recycling ICMA has addressed some major issues one of which is the feeding of the extremely light film materials. Such compelling task is achieved by a patented system that allows to continuously feed the extruders by also granting a high production yield.

Another advantage of our "one-step" approach is also to avoid expensive and "energy hungry" boiler units upstream frequently proposed by other suppliers.

Contact us

In very specific cases cascade design is advisable, for instance, when a very tight filtering process is required before the compounding stage can be started.

Here we recommend to design the line using 2 co-rotating extruders, the first to execute the efficient degassing and filtering tasks and he second for compounding . An upstream single extruder may also be considered although the overall performance level will be affected.

Contact us

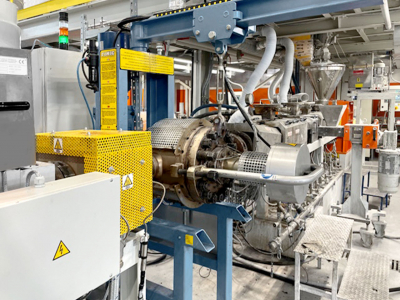

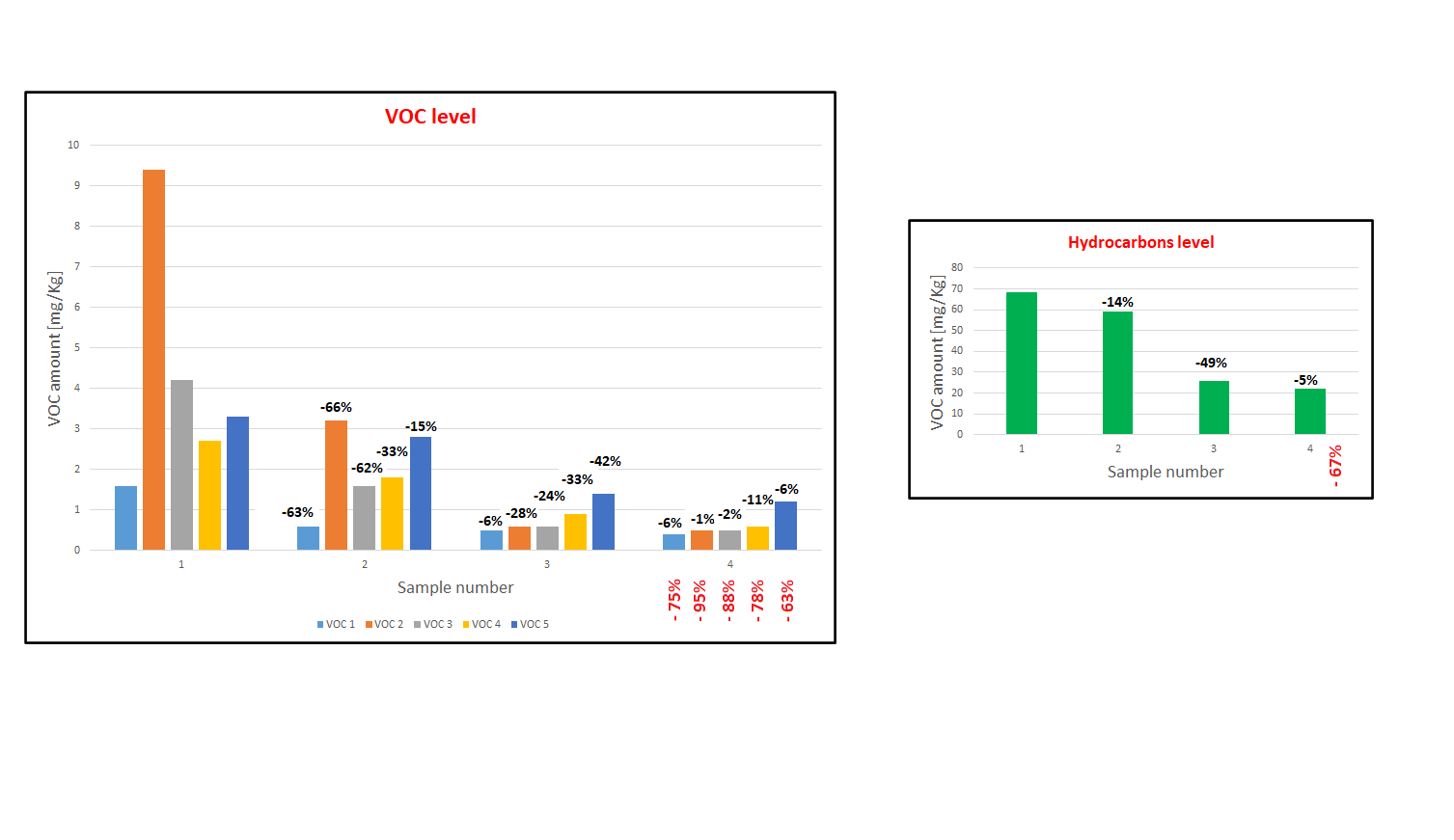

ICMA has developed a very advanced process technology to minimize contaminants up to 95% in the plastic melt during a recycling process.

Typical feed-stock waste coming from detergent bottles and fuel tanks carries unpleasant odors difficult to extract and eliminate.

This effective technology solution from ICMA is based on a combination of venting devices and stripping agent (e.g. water) that are injected

along the barrel of the co-rotating extruder through well defined injection points.

The platform is validated on industrial lines that produces in modern factories based in Europe.

Come to our INNOVATION HUB to tests your materials !

Several other materials are nowadays finding a new life with our co-rotating extruders. The more common are plastic parts of electrical devices (RAEE) or PET, ABS etc etc .

Just enquire ICMA and come to our Innovation Hub to test your scrap!

Contact us

With several lines turn-key or just extruders designed to process bioplastics (such as starch base , compounds made of PLA, PHA, PBSI, PBAT, PVOH...) ICMA can be the partner of choice to supply a reliable system. Starting in our Innovation Hub with trials to check processability of your formulation.

Contact us

Our knowledge in mixing natural fibres and a polyolefin roots back to the early 70’s when ICMA successfully pioneered, first in the World, the process technology for producing a thermoformable sheet for automotive interior trims made of virgin or recycled polypropylene and wood flour.

Today are available compounding and extrusion solutions.

Contact us

Water-soluble polymers are also a new frontier in our market with the co-rotating extruders delivering best in class results compared to other technology, for instance by avoiding pre-mix in the material preparation and enabling "one step" process task.

Contact us

The direct extrusion of sheets made of recycled resins allows the value increasing of a “poor” product.

The use of a co-rotating extruder allows the feeding of recycled scraps with a low selecting level, therefore cheaper.

From industrial wastes or selected post consumer scraps it is possible to obtain sheets having good mechanical properties that can be engineered with the addition of mineral fillers or reinforced and possibly further improved with the application of co-extruded aesthetic film.

Contact us