Advanced Recycling

The twin-screw corotating extruder is presently the most performing machinery we have at disposal, to meet the growing requirements of the recycling process.

ICMA has engineered and manufactured a series of twin-screw corotating extruders equipped with special-design venting systems capable of handling the most difficult materials. In consideration of the scraps to process, the plants can be proposed with different solutions for dosing the materials into the extruder (forced feeding system, gravimetric or volumetric dosing system) with or without side feeding units and with enhanced venting system for humidity, monomers and solvent extraction.

For pelletizing purposes, some different systems could be used, such as strand-type pelletizing systems, liquid-ring type pelletizer, or under-water pelletizer.

Machinery throughputs are strictly connected to the recycled material, to the requested process formula, and to the necessary filtering degree.

The twin-screw low-speed corotating extruder belonging to the MCM/Series is particularly suitable for very light products that need a high intake capability of screw feeding and constant control of the extruder process.

Examples

Recycling, venting, and pelletizing of polymers modified with mineral fillers or fibers glass.

→ PE – PP from foils

→ PA.6 – PA.66 from ground scraps

→ PET from ground scraps

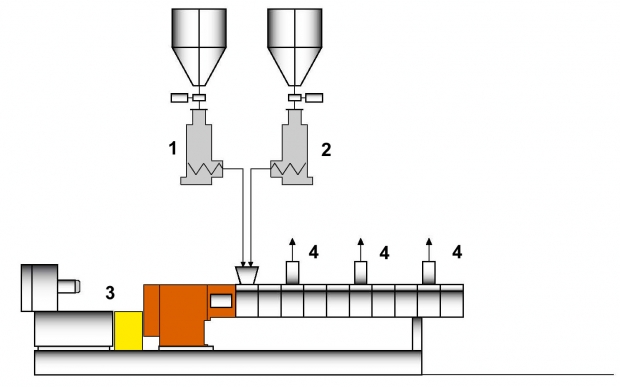

1 dosing unit for polymer, 2 dosing units for additives, 3 MCM corotating extruders, and 4 high-performing venting systems.

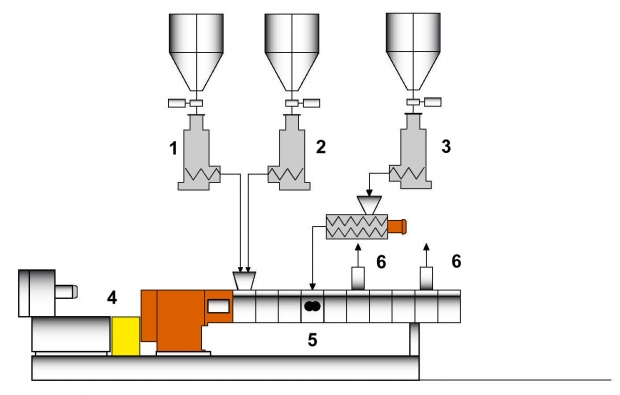

1 dosing unit for polymer, 2 dosing units for additives, 3 dosing units for fillers/fibers, 4 MCM corotating extruders, 5 side feeding units, and 6 high-performing venting systems.