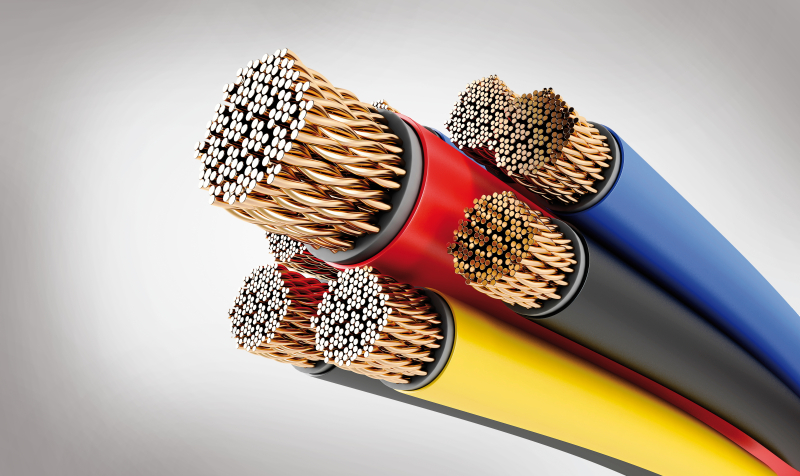

Cables Compounding

The twin-screw corotating extruder is greatly used for processing those raw materials particularly sensitive to thermal and mechanical stress, for example in cable production.

In this area, ICMA has developed a very skilled technology for the production of some types of compounds, such as Cross-Linked compounds silane/peroxide-based or peroxide base for low-medium voltage (XLPE), Flame-Retardant compounds (FR), and “Halogen-Free” compounds (HFRR). In these applications, the mixing quality – further to the high dispersion degree – and temperature control are key for good processing.

Examples

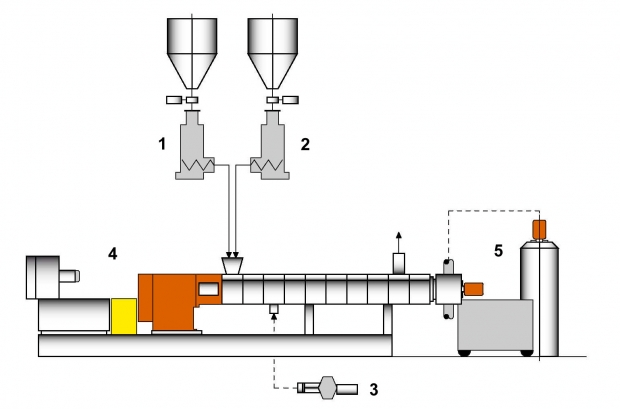

Crosslinked (XLPE) - silane and peroxide base:

1 gravimetric feeder for polymers, 2 gravimetric feeder for additives, 3 gravimetric feeder for liquid components, 4 MCM corotating extruder, 5 hot-face pelletizer.

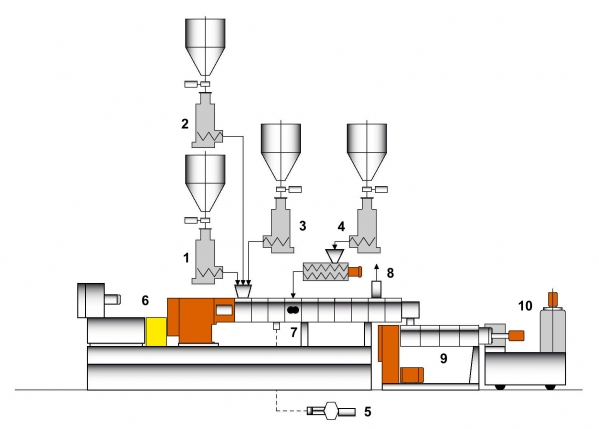

Crosslinked (XLPE) - peroxide base:

1-4 gravimetric feeder, 5 gravimetric feeder for liquid, 6 co-rotating extruder, 7 lateral feeder, 8 degassing unit, 9 single screw extruder, 10 pelletizer.