Sheets made of Recycled materials & Recoboard technology

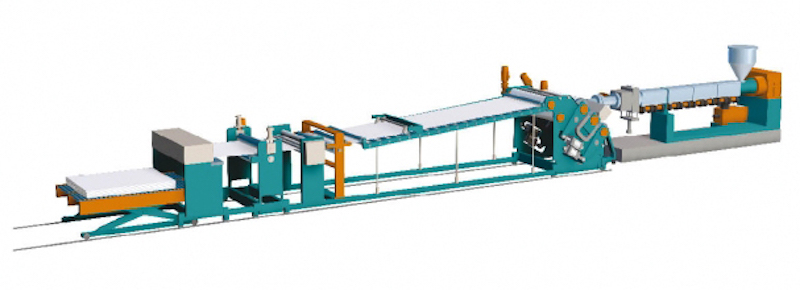

The direct extrusion of sheets made of recycled resins allows the value to increase of a product.

The use of a co-rotating extruder allows the feeding of recycled scraps with a low selecting level, therefore cheaper.

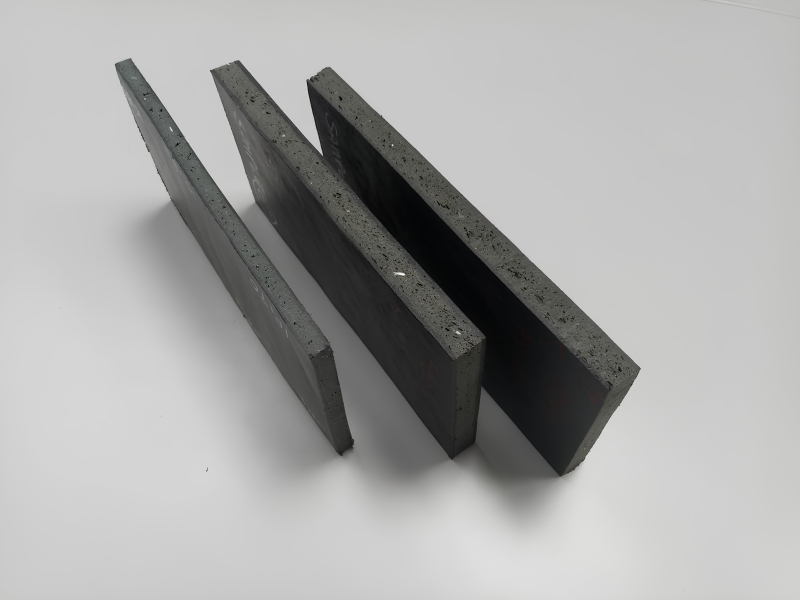

From industrial wastes or selected post-consumer scraps, it is possible to obtain sheets having good mechanical properties that can be engineered with the addition of mineral fillers or reinforced and possibly further improved with the application of the co-extruded aesthetic film.

RECOBOARD is a highly-innovative, new technological solution that simultaneously tackles two global environmental big issues, post-consumer plastic waste and deforestation.

The technology, supported by the European Union’s H2020 SME Instrument, and continuously upgraded by Icma's team, takes low-grade mixed plastic waste and converts it directly into a high-performance and cost-effective boards that can find several applications, like for instance in construction as alternative to plywood.

Not only does this technology provide an economic use for low-grade waste plastic that would otherwise likely NOT be recycled, but it also reduces demand for plywood – a major cause of global deforestation.

According to the UN Food & Agricultural Organisation, in 2016 Europe was a net importer of $3.9 Billion of plywood, with a large portion of that material coming from far-away locations such as China, Brazil, Canada and The Russian Federation.

During the same period, Europe exported 8 million tonnes of waste plastic to China.

The RECOBOARD technology opens up the potential for a complete paradigm shift away from the current model of dumping waste plastic on one hand, and importing products made from active deforestation on the other.

Instead, our technology-led vision is one of converting waste plastic locally into a product to be used locally, that is in turn also fully recyclable.