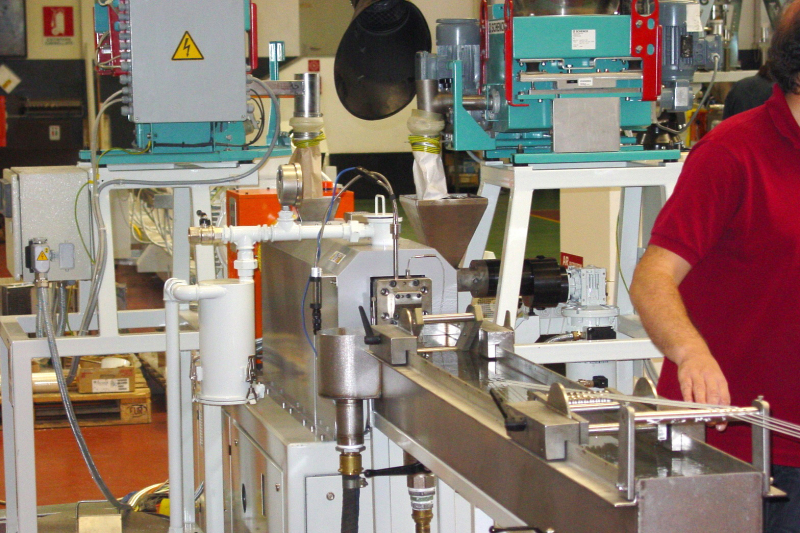

Lab Scale Units

What is a Pilot and Lab Extruder and its function?

An ICMA's Lab extruder is a small extruder able to produce, in small batches, products, and compounds by mirroring what a bigger industrial extruder can do.

Brief description and technical features:

→ ICMA's Lab systems are perfectly equipped for use as development units with the same process engineering features & equipment applied to production scale extrusion lines in order to ensure reliable and safe scale-up. It is extremely user-friendly also of its compact dimension

→ Modular screws of the co-rotating extruder with several geometries and different barrel designs are combined with a wide range of ancillary equipment to deliver maximum flexibility

Who should buy:

→ Companies aiming at studying new processes or/and upgrading existing formulations before going to real production. Also good for small production batches.

The advantages you can achieve by having such a system are:

→ Minimize operational risks of new formulation before going into production

→ Minimize time to market and “payback” period of new developments

→ Minimize risks related to “information protection” issues compared to external development

→ By decreasing the risks/costs above detected “returns” of new developments are maximized

| Screw Diameter (mm) | Da/di | Md/a^3 (Nm/cm^3) per shaft | Maximum Screw Speed (U/min) |

|---|---|---|---|

| 25 | 1,55 | 15 | 1200 |

| 30 | 1,55 | 18 | 1200 |