PROCESS TECHNOLOGY

CO-ROTATING EXTRUDERS enjoy segmented screws & barrels to deliver a unique performance.

Co-rotating twin screw extruders occupy a dominant position among extruders and are widely used in a great variety of applications. The typical scope of application is compounding, and processing of plastics, although this technology is finding more and more industrial spaces, like in rubber, composites and food processing, thanks to its versatility, high performance and technical reliability.

But what is a co-rotating extruder?

A twin screw extruder is an advanced engineered machine consisting of two inter-meshing co-rotating screws mounted on splined shafts along a process barrel. The screws are made in modular segmented sliding disks with different geometries to process a great variety of materials. In addition this screw design is self-wiping, a feature that eliminates stagnant zones over the entire length of the process section. The final results are high mixing efficiency with perfect self-cleaning and quality driven with sizeable output results.

Co-rotating inter-meshing designs were developed and applied first time in the 30's for mixing and pumping ceramic paste. The first commercial machine of this type was invented by Colombo from LMP (Italy) for thermoset and PVC processing.

ICMA has made proper this precious background and today can offer a modern and advanced range of co-rotating extruders that goes from standard co-rotating twin screw extruders up to high-torque version to cover a very wide range of applications.

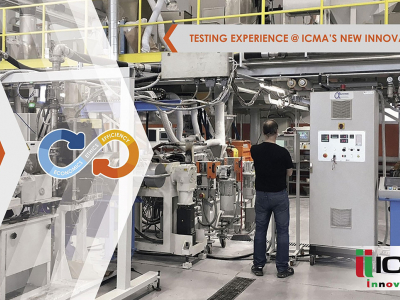

ICMA has created a unique place, for our existing and potential customers, for testing formulations, running small production trials, developing new projects on our co-rotating extruders.

Contact us