Masterbatch

What is Masterbatch and its usage?

A Masterbatch is a concentrated mixture obtained by the distribution of colors and additives into a polymer carrier by heat treatment and in-particularly a high-shear mixing extruder.

The preparation of a Masterbatch represents a demanding process since a high content of pigments or additives has to be mixed into a polymeric matrix.

ICMA is specialized in such processes and can boast different installations in this specific sector.

→ MASTERBATCH WITH ORGANIC (Colour) O INORGANIC (CaCO3, TiO2) PIGMENTS

→ ADDITIVES MASTERBATCH

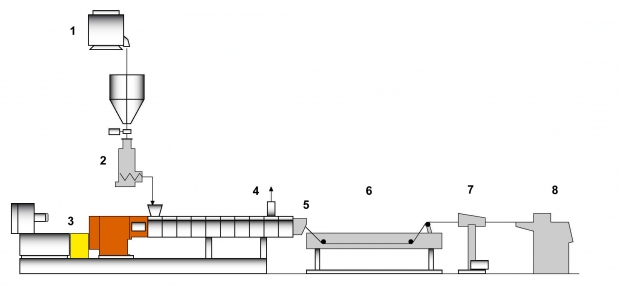

Masterbatch obtained from premixed raw materials:

1 turbo-mixer, 2 volumetric feeders, 3 MCM co-rotating extruder, 4 degassing, 5 strands-die, 6 cooling tanks, 7 air blade, 8 pelletizer

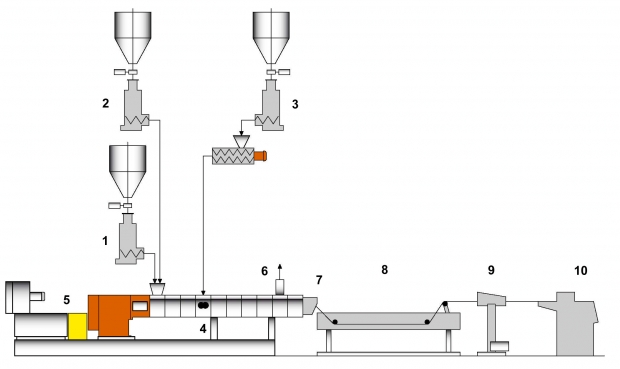

Masterbatch obtained with the separate feeding of the different ingredients:

1 gravimetric feeder for polymer, 2 gravimetric feeder for additives, 3 gravimetric feeder for pigments, 4 side feeding unit, 5 MCM co-rotating extruder, 6 degassing, 7 strands-die, 8 cooling tanks, 9 air blade, 10 pelletizers.