Co-rotating extruders for advanced recycling

19/02/2013

Due to its great use in the packaging industry, plastics represent one of the main components of solid waste. Plastics are not biodegradable (with some exceptions) and it is therefore extremely important to increase recycling activities. The advantages given by plastics recycling are mainly:

1. Waste reduction

2. cost decrease of the final product

3. energy consumption reduction

4 environmental protection, due to emissions reduction

5. Oil saving.

Starting from waste/scraps (PET, PVC, HDPE, LDPE, PS, PA, and ABS are the most commonly recycled plastics), through plastics recycling it is possible to obtain a new end-product with high technical features.

A correct process design and extrusion technology are key factors to grant quality products and investment returns.

In the plastic recycling industry, an innovation element is the use of co-rotating extruders, which is becoming more, and a more winning solution compared to traditional technologies (such as single-screw extruders) in facing most of the issues and challenges that plastic processors have to address today.

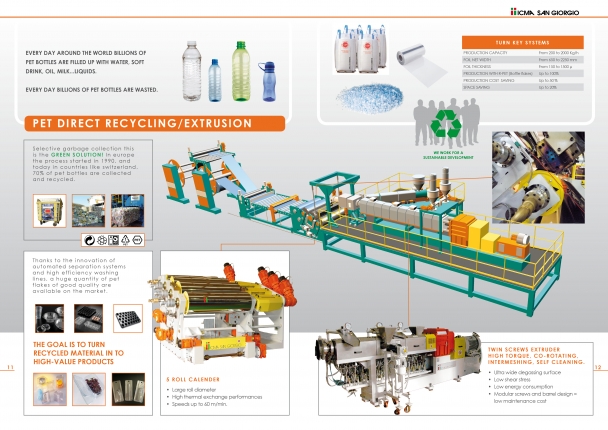

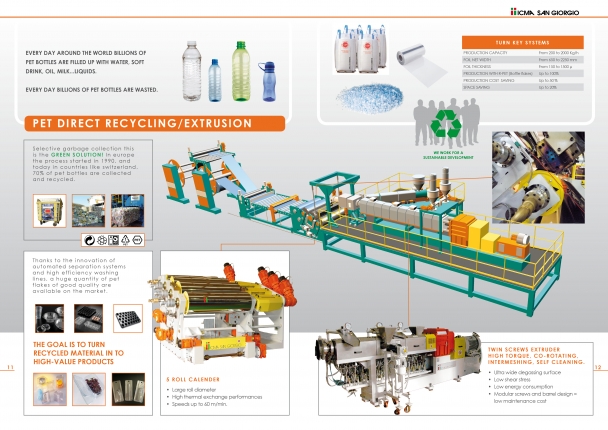

Icma San Giorgio has developed advanced recycling systems based on co-rotating extruders dedicated to the recovery of single polymers (HDPE, PA, PET, etc.), miscellaneous post-consumer materials (mixed plastics) highly contaminated plastic industrial waste general scraps (e.g. tire rubber). Taking most of their technical features from its MCM – “high torque” family, these specially designed extruders use particular degassing and filtering systems able to treat demanding scrap materials so that current demand coming from many processors can be matched at the highest quality standard.

1. Waste reduction

2. cost decrease of the final product

3. energy consumption reduction

4 environmental protection, due to emissions reduction

5. Oil saving.

Starting from waste/scraps (PET, PVC, HDPE, LDPE, PS, PA, and ABS are the most commonly recycled plastics), through plastics recycling it is possible to obtain a new end-product with high technical features.

A correct process design and extrusion technology are key factors to grant quality products and investment returns.

In the plastic recycling industry, an innovation element is the use of co-rotating extruders, which is becoming more, and a more winning solution compared to traditional technologies (such as single-screw extruders) in facing most of the issues and challenges that plastic processors have to address today.

Icma San Giorgio has developed advanced recycling systems based on co-rotating extruders dedicated to the recovery of single polymers (HDPE, PA, PET, etc.), miscellaneous post-consumer materials (mixed plastics) highly contaminated plastic industrial waste general scraps (e.g. tire rubber). Taking most of their technical features from its MCM – “high torque” family, these specially designed extruders use particular degassing and filtering systems able to treat demanding scrap materials so that current demand coming from many processors can be matched at the highest quality standard.

LATEST ARTICLES

27/05/2025

ICMA at GreenPlast from 27-30 may in Milan - Hall 14 stand B42

15/04/2025

ICMA at Chinaplas 2025 in Shenzhen, from April 15th to 18th / Visit us at Booth 10G68

01/04/2025

ICMA attending next PRS in Amsterdam 1-2 April 2025

19/02/2025

ICMA @PLASTICO BRASIL STAND from 24-28 March - E43 – HALL 2

19/12/2024

New technologies for the Circular Economy with Recoboard

⤺ Back